Descriptive for Bidders

Download Bid Description

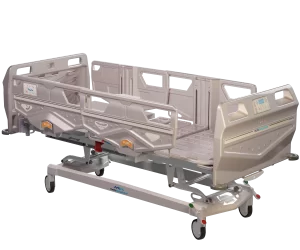

CAMA DIAMOND INFANTIL MT-154

Present ANVISA Registration

Structure:

Tubular structure with sheets of varying thicknesses of carbon steel, designed to withstand the efforts and nominal load of the product. The chassis consists of a structure of 50 x 30 x 2.0 mm tubes with 1/4″ thick sheets. The bed frame is made of 50 x 30 x 2.0 mm tubes with 3/8″ thick sheets. The metal structure of the bed consists of four articulated sections made with 30 x 20 x 1.2 mm tubes and 3/16″ thick sheets.

Optional:

• Similar structure with the same characteristics in stainless steel

• Similar structure with the same characteristics in aluminum

• Bed frame made of a “U” profile in carbon steel with 3.2 mm thickness, available in carbon steel, stainless steel, or aluminum

Bed:

• Structured thermoplastic bed, with patient containment and mattress limiter.

The bed platform is independently secured to the four articulated sections of the metal frame, ensuring durability and stability. Optional:

• Removable structured thermoplastic bed

• Removable bed made of perforated or smooth stainless steel sheet

• Removable bed made of perforated or smooth carbon steel

• Removable bed made of perforated or smooth aluminum sheet

• Removable bed made of ABS

• Bed made of wood sheet (MDP, MDF, or TS)

Movement:

Vertical movement is performed by a carbon steel mechanical system that converts the horizontal linear movement of the motors into the vertical movement of the bed, enabling height adjustment. Bed movements are performed using four motors and an adjustable system with six positions. The movements performed by the bed are: Fowler, Semi-Fowler, backrest elevation, leg elevation, bed elevation and lowering, Trendelenburg, Reverse Trendelenburg, recliner, vascular, cardiac, and auto-contour. Optional Movement System:

• Similar mechanical system with the same characteristics in stainless steel

• Similar mechanical system with the same characteristics in aluminum

• Retractable crank Optional Motorization:

• Two motors

• Three motors

• Five motors • Optional Movements:

• CPR (quick release)

• CPR + bed lowering to minimum position ONE TOUCH

• Cardiac recliner

• ONE TOUCH recliner

Electronic Controls:

• Mobile hand control with lock Optional:

• Mobile hand control without lock

• Horizontal control on siderail

• Vertical control on siderail

• Supervisor with display on siderail

• Supervisor without display on siderail

• Supervisor with display on footboard

• Supervisor without display on footboard

• Supervisor control on bed frame structure

• Mobile satellite supervisor with lock

• Mobile satellite supervisor with cord

• Casters and Brake System:

• The bed is equipped with 4″ diameter thermoplastic casters, providing floor protection with low noise during movement and excellent load capacity.

• The braking system is individually applied to each of the four casters, activated by foot pedals with a stationary lock function for rotation and translation.

Optional Casters:

• 3″ diameter thermoplastic or galvanized casters with or without brakes

• 4″ diameter galvanized casters with or without brakes

• 5″ diameter thermoplastic or galvanized casters with or without brakes

• 6″ diameter thermoplastic or galvanized casters with or without brakes

• 8″ diameter thermoplastic or galvanized casters with or without brakes

• 10″ diameter thermoplastic or galvanized casters with or without brakes

• 4″ diameter thermoplastic casters with total and directional brake

• 5″ diameter thermoplastic casters with total and directional brake

• 6″ diameter thermoplastic casters with total and directional brake

• 8″ diameter thermoplastic casters with total and directional brake

Optional Brake Systems:

• Individual braking system on two diagonal casters

• Individual braking system on the two footboard casters

• Individual braking system on the two headboard casters

• Total and directional brake system

• Siderails and Siderail System:

• Set of four wooden siderails (MDF, MDP, or TS) with enclosed system.

Retractable system with locking mechanism. Optional Siderails:

Six polyethylene siderails, flexible enclosed model

Four polyethylene siderails, flexible model with escape route

Four polyethylene siderails, classic enclosed model

Four polyethylene siderails, new premium enclosed model

Four polyethylene siderails, new premium model with escape route

Two metal tube siderails (carbon steel, stainless steel, or aluminum) 3/4″ x 1.2 mm or wooden (MDF, MDP, or TS) with escape route

Four metal tube siderails (carbon steel, stainless steel, or aluminum) 3/4″ x 1.2 mm enclosed

Two metal tube siderails (carbon steel, stainless steel, or aluminum) 3/4″ x 1.2 mm or wooden (MDF, MDP, or TS) enclosed

Optional Siderail System:

Compact system with lock

Universal up-and-down system with lock

Stacking system

Headboard, Footboard, and Headboard Attachment:

Headboard and footboard made of high-impact injected polyethylene, flexible model

Attachment with lock and removable

Optional Headboard and Footboard:

Made of high-impact injected polyethylene, classic model

Made of high-impact injected polyethylene, new premium model

Made of metal tubes (carbon steel, stainless steel, or aluminum) 3/4″ x 1.2 mm

Made of wood (MDF, MDP, or TS)

Optional Headboard Attachment:

Removable attachment without lock

Fixed attachment

Surface Finish of the Metal Structure:

The entire carbon steel structure receives anti-rust chemical treatment and electrostatic powder coating, baked at 220°C (428°F) in an oven, which increases the chemical resistance of the structure.

Optional:

High-gloss polishing for stainless steel, ensuring excellent asepsis

Chassis Finish:

Partial coating for the chassis in thermoplastic only over the wheels

Optional:

No coating

Full chassis coating in thermoplastic

Partial or full coating in aluminum

Partial or full coating in painted carbon steel

Partial or full coating in stainless steel

Technical Data:

Fowler Backrest: 75° ~ 77° Incline

Fowler Legs: 20° ~ 23° Incline

Trendelenburg: 0° ~ (-15°)

Reverse Trendelenburg: 0° ~ 15°

Maximum Elevation: 0.68 m (26.77″)

Minimum Elevation: 0.33 m (12.99″)

Bed:Length: 1750~1950 mm (68.90″~76.77″)

Width: 830 mm (32.68″)

Height: 330~680 mm (12.99″~26.77″)

Total:Length: 2080~2280 mm (81.89″~89.76″)

Width: 1090 mm (42.91″)

Height: 330~680 mm (12.99″~26.77″)

Maximum Working Load: 280 kg (617 lbs)

Maximum Patient Weight: 250 kg (551 lbs)

Optional:

Bed:

Length: 1700~2280 mm (66.93″~89.76″)

Width: 700~1100 mm (27.56″~43.31″)

Height: 300~830 mm (11.81″~32.68″)

Total:

Length: 2000~2400 mm (78.74″~94.49″)

Width: 1000~1500 mm (39.37″~59.06″)

Height: 300~830 mm (11.81″~32.68″)

Maximum Working Load / Maximum Patient Weight:

Maximum Working Load: 180 kg (396 lbs) / Maximum Patient Weight: 150 kg (330 lbs)

Maximum Working Load: 280 kg (617 lbs) / Maximum Patient Weight: 250 kg (551 lbs)

Samples may be requested at the discretion of the hospital.